Services

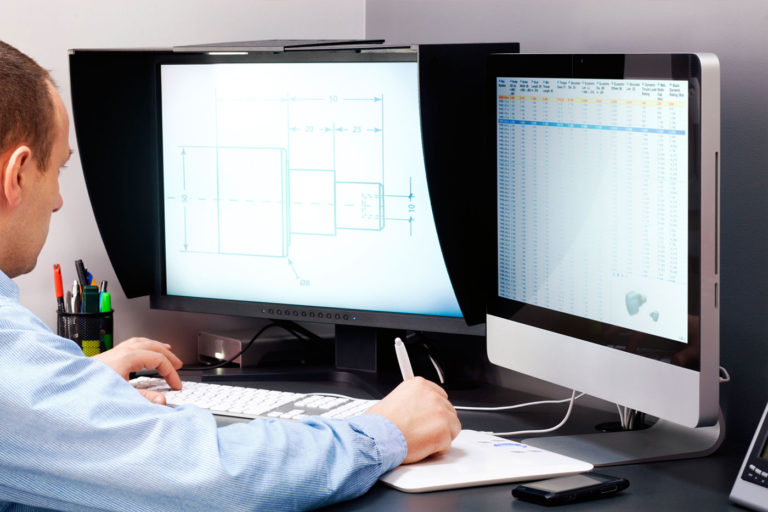

Engineering

Von der CAD-Daten-Erstellung von 2D-Zeichnungen über die Produktentwicklung bis hin zum Reverse Engineering: Wir bieten Ihnen den Mehrwert, der Sie weiterbringt.

3D-Druck

Wir drucken Formen für komplexeste Teile, die konventionell nicht herstellbar sind. Als Dienstleister drucken wir aber auch Gussformen für andere Giessereien. Dank der 3D-Drucktechnik lassen sich im Bereich der Architektur neue, ungeahnte Formen gestalten.

Guss in allen handelsüblichen Legierungen

Wir sind in der Lage, jegliche handelsübliche Legierung zu vergiessen – ob inhouse, wenn es sich um Aluminium und Kupferwerkstoffe handelt, oder bei unseren Partnern, im Fall von eisenbasierten Werkstoffen.

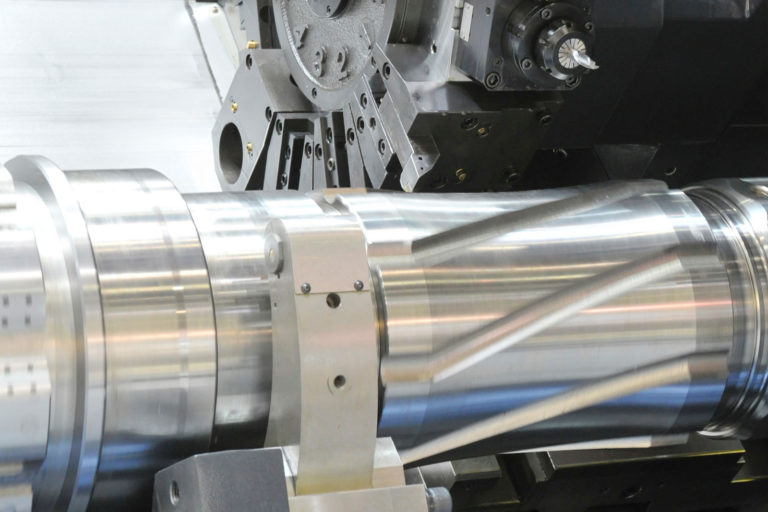

Mechanische Bearbeitung

Neben dem Guss gehören auch mechanische Bearbeitungen, Oberflächenbehandlungen und Druckprüfungen bis hin zu Abnahmen durch Prüfinstitute zu unserem Portfolio. So erhalten Sie von uns eine einbaufertige Komponente – und sparen sich die Zeit und die Mühe, mit mehreren Ansprechpersonen die gleichen Diskussionen zu führen. Unser Credo heisst: «Gewünschte Qualität zum gewünschten Zeitpunkt aus einer Hand».

Oberflächenbehandlung

Zusammen mit unseren Partnern bieten wir Ihnen jede erdenkliche Oberflächenbehandlung an: Versilbern, Vernickeln, Verchromen, Eloxieren und mehr.

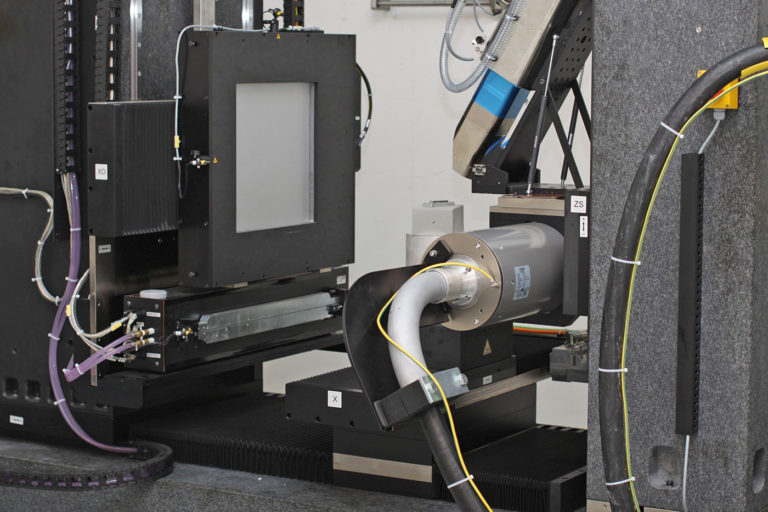

Dichtigkeitsprüfungen

Als Hersteller mit SVTI-Zulassung können wir sämtliche Dichtigkeitsprüfungen mit Helium, Luft oder Wasser durchführen.

Montagen und Teilmontagen

Wir können Ihnen sowohl fertig zusammengebaute Komponenten als auch Teilkomponenten liefern – Sie haben die Wahl.

Zerstörende und Zerstörungsfreie Prüfungen

In Zusammenarbeit mit unserem Prüfpartner Qualitech AG bieten wir Ihnen sämtliche zerstörenden und zerstörungsfreien Prüfungen für Gusskomponenten an.

Production Types And Dimensions

| Moulded in a moulding line | up to 650 × 500 × 250/250 mm |

|---|---|

| Hand moulded | up to 3000 × 2000 × 1200 mm |

| Aluminium alloys | up to 500 kg unit weight |

| Copper alloys | up to 450 kg unit weight |